Technology Project

MultiBeAM

Objective:

Multimaterial processing by means of additive manufacturing

Partners:

Duration: 01.02.2017 - 31.01.2020

Objective

Within the MultiBeAM technology project, completely new multi-material components in the combinations:

• Metal-Metal,

• Metal-Ceramics,

• Ceramic-Ceramic/Plastic,

can be generated. These are intended to highlight the potential of AgF to open up new fields of application in innovative key technologies and thus make a significant contribution to their economic establishment. In accordance with the requirements of the end users, theme packages must be extracted which both reflect concrete requirements of the industry and enable a broad exploitation of the results in established value creation networks. In addition to the systematic further development of process concepts, these also include the provision of material-specific basic knowledge and the adaptation of the corresponding process chains. The general feasibility of this novel approach is to be demonstrated by means of application-relevant components and incentives for industrial use are to be created.

Planned research work and cooperation partners involved

Generative powder bed and nozzle-based processes (e.g. laser generation, selective laser melting) are redesigned in terms of system technology in order to be able to vary the material composition of the generated components during production. The selection of the material pairings consisting of metal and/or ceramics as well as the definition of the demonstrators, supported by a high proportion of industrial partners, is oriented very closely to future fields of application in aerospace, optics, energy and medical technology. Four user topics (UT), within which the cross-thematic work packages of the MultiBeAM technology project are to be worked on, were identified in cooperation with the project partners.

UT1 Ti-/Ni-based components with local use of steel & high temperature alloys

Complex components in the hot gas area of gas turbines are exposed to locally varying high thermo-mechanical loads. As a result of high operating temperatures and temperature gradients caused by internal cooling structures, geometric component distortion and mechanical damage occur. Through local optimization of the properties, such components can be better adapted to the respective load conditions, the efficiency can be increased and/or the system weight can be reduced and thus the emissions can be lowered.

UT2 High-precision metal-ceramic composite components for the optical industry

In the manufacture of complex, high-precision assemblies made of high-performance ceramics, conventional abrasive shaping processes reach their technical and economic limits. Here, the processes of high-precision laser cladding or laser sintering offer astonishing potentials for the generation of structural elements, optical systems or lightweight structures for space applications.

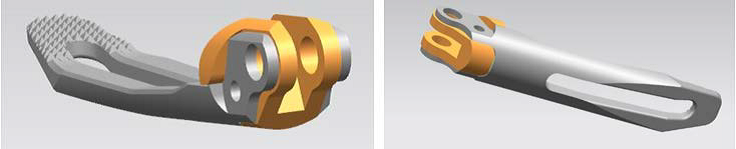

UT3 Bipolar surgical instruments (metal-ceramic cutting tool)

Only through the combination of material properties (hardness, ductility, electrical and thermal conductivity) does the metal-ceramic pairing enable the production of medical instruments for minimally invasive surgery, which are characterized by a very high functional density (sharp cutting edges, gripper, endoscope, electrical contacts, media guidance, supply and suction) and very good resistance (high mechanical stability, dimensional stability, sterilizable, stable against corrosion and plasma).

UT4 Customized implants (high-quality shell) / lightweight, cost-effective core

Individualized implants are to be used with the combination of a planar material application in addition with polyjet nozzles for the construction of medical and dental components. For this application topic, filled plastics are therefore to be used initially as the starting material, which are converted into a pure ceramic after the subsequent debinding and sintering process.

© Olympus