Technology Project

IMProVe

Objective:

Overcoming process limits in additive manufacturing by combining innovative materials, equipment and processes

Partners:

![]()

Duration: 01.05.2017 - 30.04.2020

Resource-efficient and hybrid manufacturing by overcoming process limits

The qualification of further materials and processes to minimize the limited variety of materials, the increase of process stability as well as the combination of additive processes are the focus of the developments. On the basis of exemplary geometry demonstrators, hybrid manufacturing approaches from laser cladding, powder bed processes (electron beam melting / electron beam melting EBM, laser beam melting / laser beam melting LBM) and conventional processing are to be developed. This is intended to overcome manufacturing limitations so that in future cost and productivity restrictions can be minimized or eliminated and the considerable expansion of the industrially relevant field of application of additive processes can be promoted.

Approach

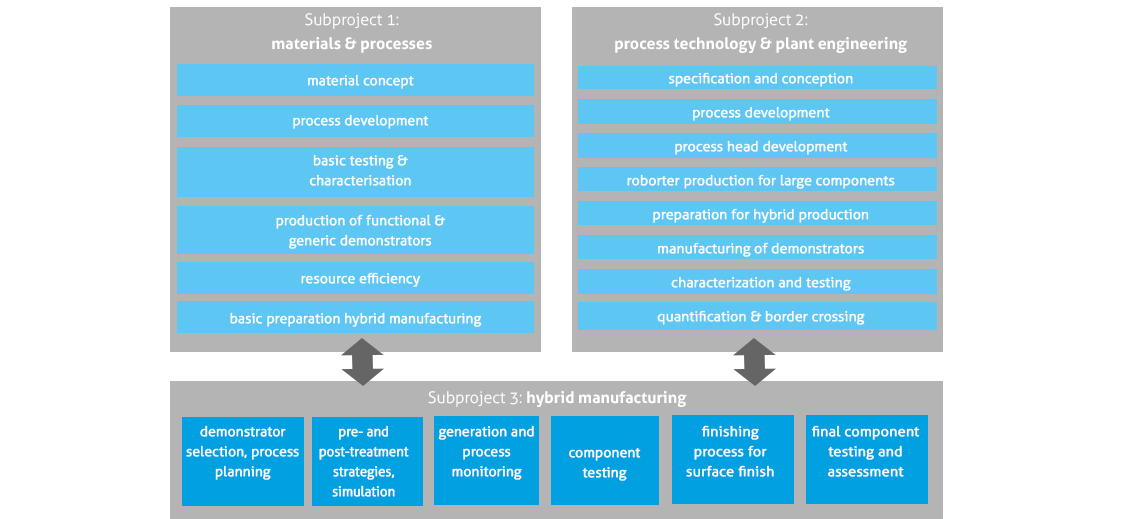

The IMProVe technology project consists of three interlinked sub-projects:

Materials and processes

Steels

|

Ceramics

|

Ceramics

|

Fe-Ni-alloy

|

|||

|

|

|

|

|||

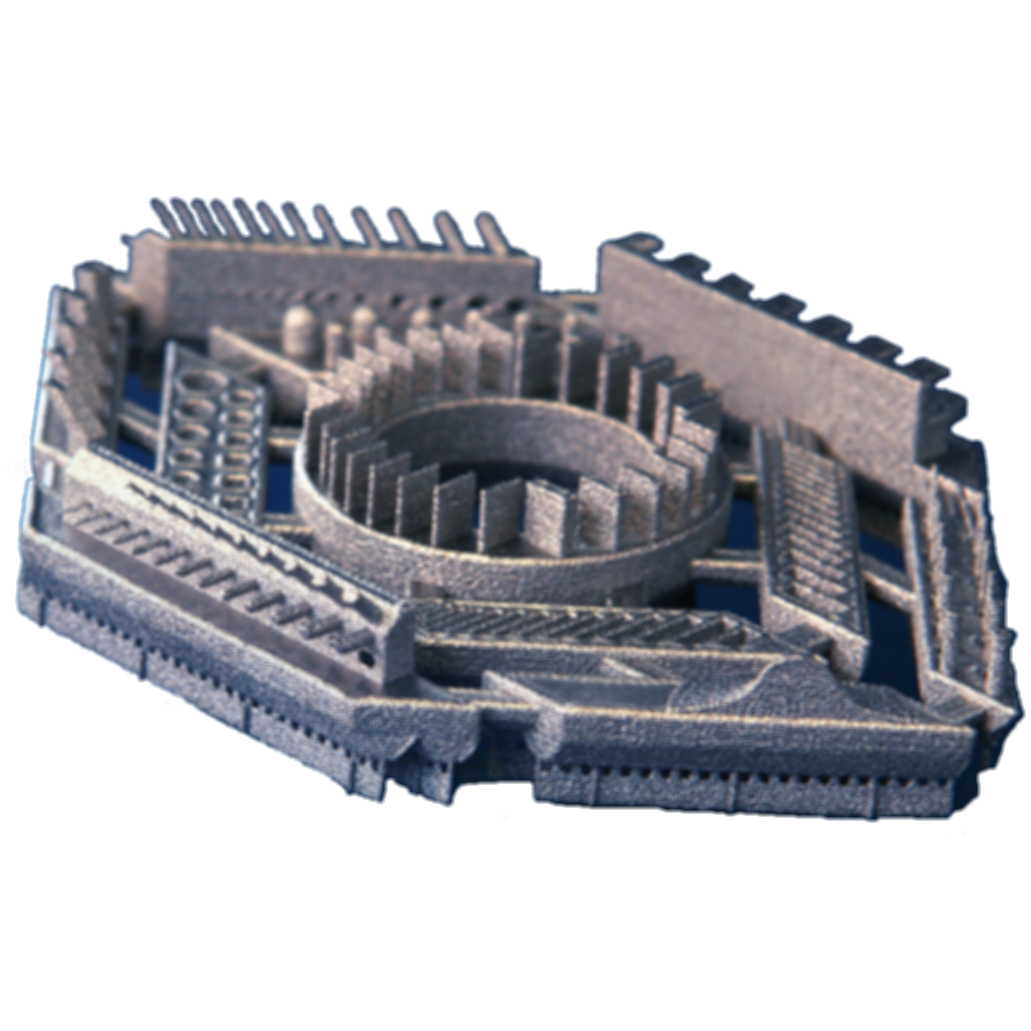

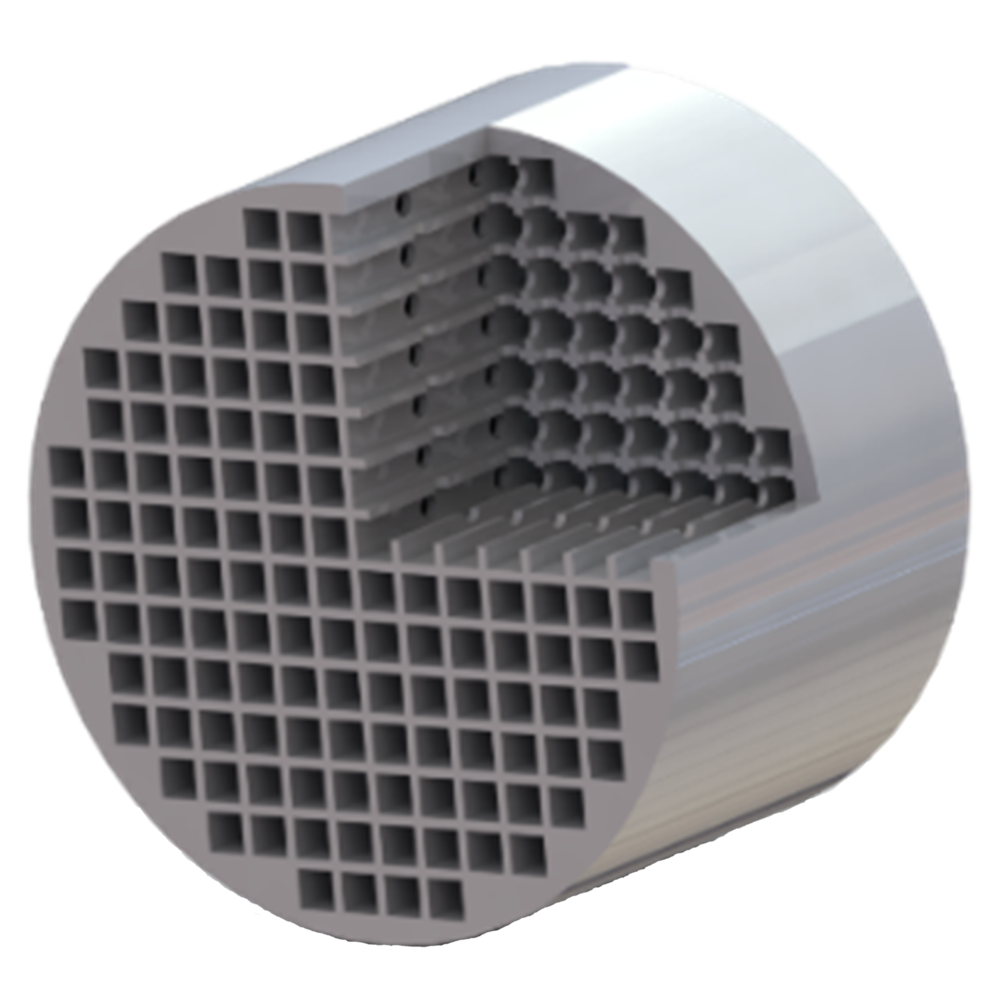

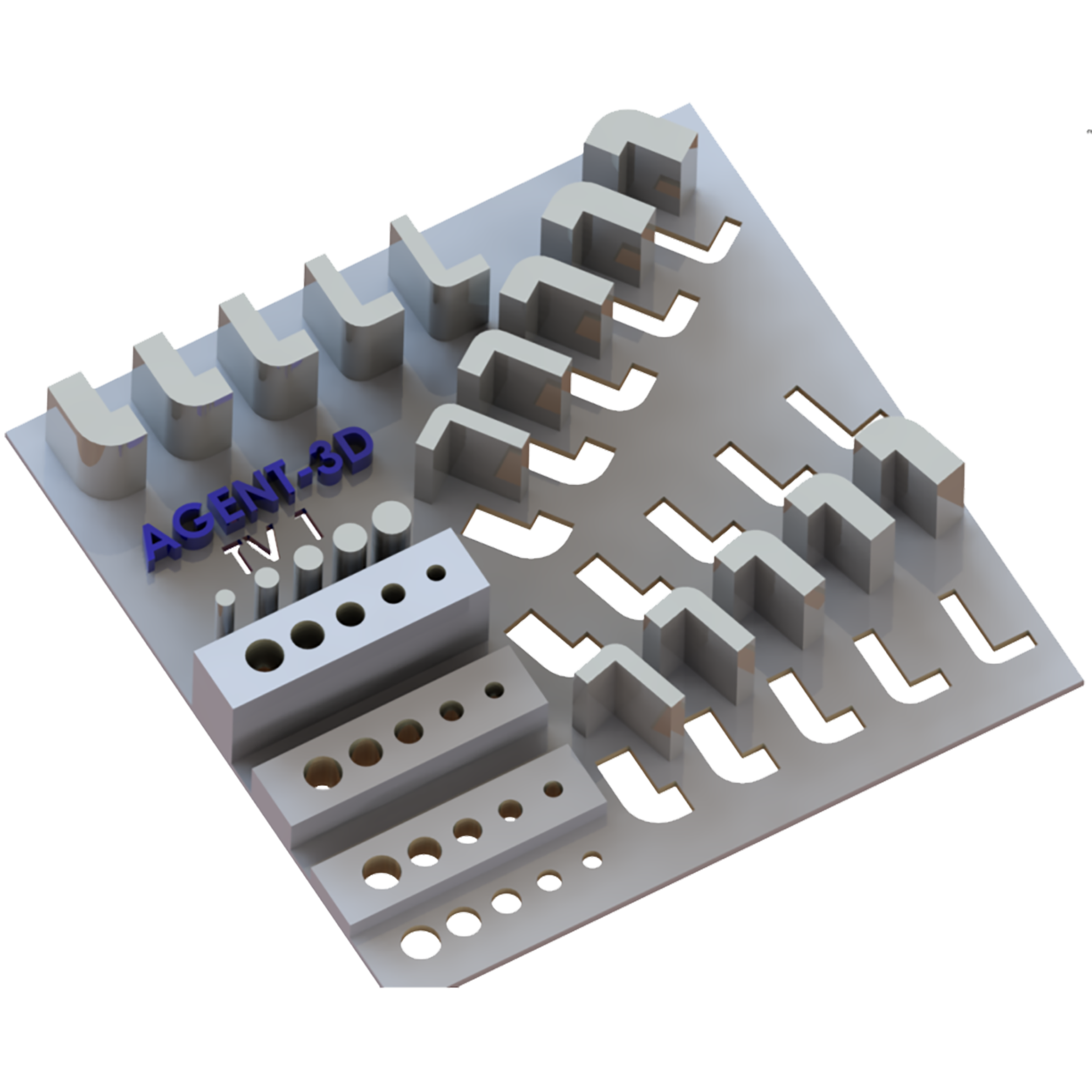

Generic ceramic and metal demonstrators

The metal demonstrator is a freely available design demonstrator based on the template of the RTC Duisburg (link to download CAD file). The ceramic demonstrators of the Fraunhofer IKTS are adapted to the respective fields of application (porous structures, high-performance ceramics).

The aim is to demonstrate that a form-complex structure is possible with the new materials. The demonstrators will be built with new powder as well as with recycled surplus powder. In a target-performance comparison between CAD and demonstrator, the dependence of the geometric possibilities of technology and material will be quantitatively investigated.

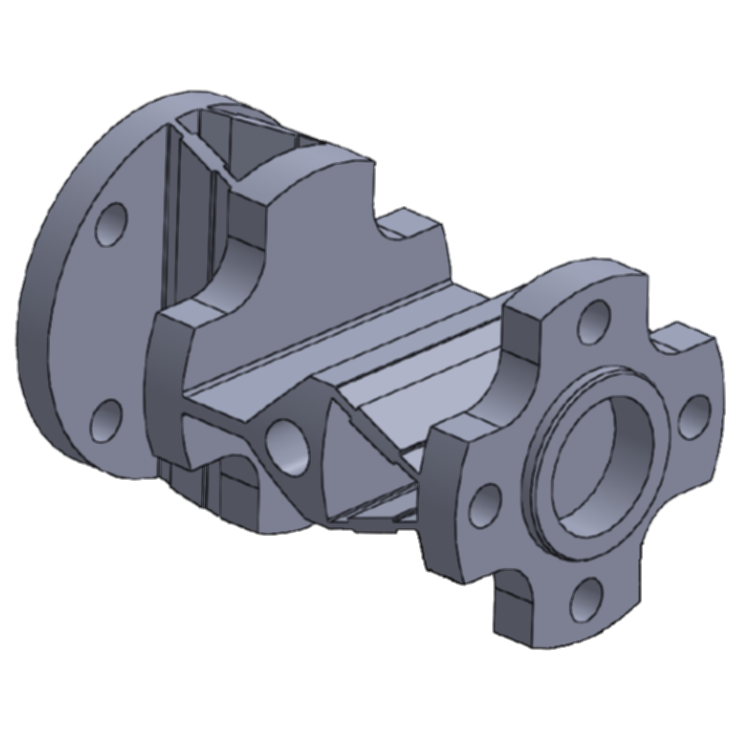

Functional demonstrator (© Airbus)

It is a real component from the field of satellite technology, which thus already exists conventionally and in a powder bed made of INVAR. The aim is to demonstrate that the new material Super-INVAR can also be used to produce such a complex-shaped structure with cost-saving potential compared to conventional production. The mechanical properties of INVAR are to be retained while improving functionality.

Process technology and plant engineering

|

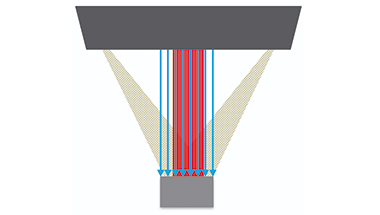

Conventional laser head Conventional laser head |

Coaxial direct diode laser (kDDL) |

Technology development laser deposition welding

In order to improve quality and resource efficiency in laser cladding, the aim is to monitor the filler metal supply and other process signals, which are correlated with numerical predictions. The development of coaxial direct diode lasers (kDDL) for both wire and powder processing also enables good material and energy efficiency.

Further developments in process simulation will also improve the predictability of distortion and residual stress as well as parameter design.

By using robot-guided contour recognition systems, geometric process limits in the manufacture of large components are overcome.

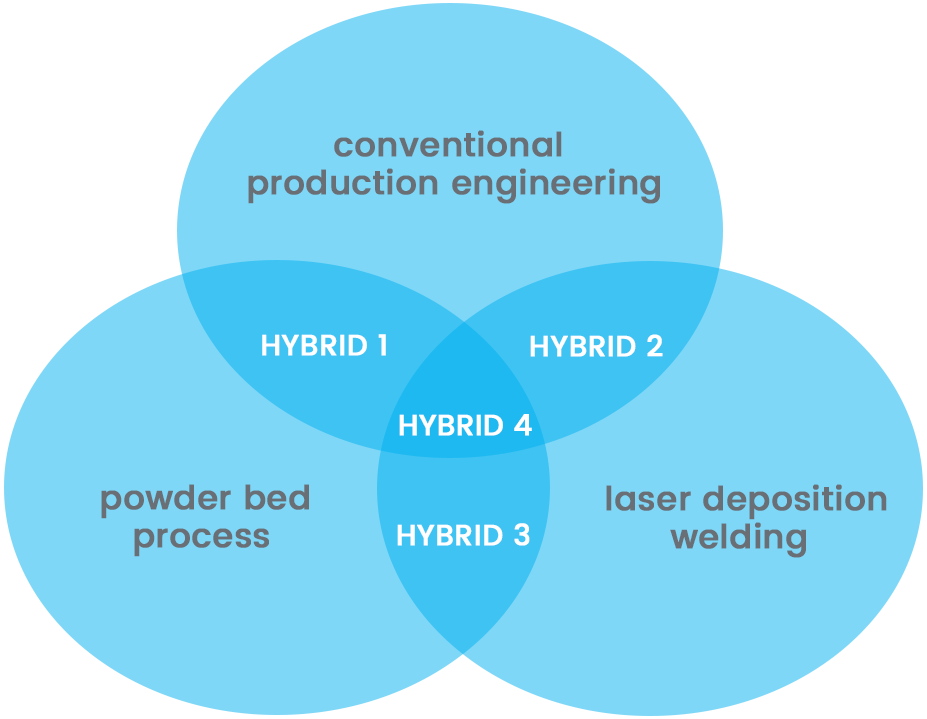

Hybrid manufacturing in the project

Demonstrators |

|||

HYBRID 1 - cutting tool |

HYBRID 2 - turbine housing |

||

|

|

|

||

Requirements• Highest wear properties • High stability • Reduction of the post-processing effort Barriers to be overcome

• Evaluation of new materials (particle reinforced materials) • Cross-process manufacturing (conventional and additive) • Material combinations |

• Compliance with aviation quality standards • Component dimensions of over one meter

• Reproducibility • Resource efficiency (materials and energy) through process head development and process simulation • Process combinations (conventional and additive) • Production of large components Robotics |

||

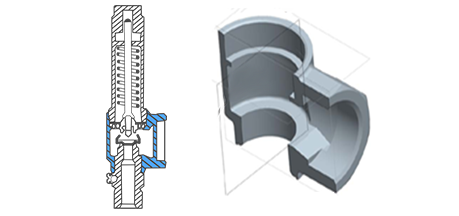

HYBRID 3 - housing of a safety valve |

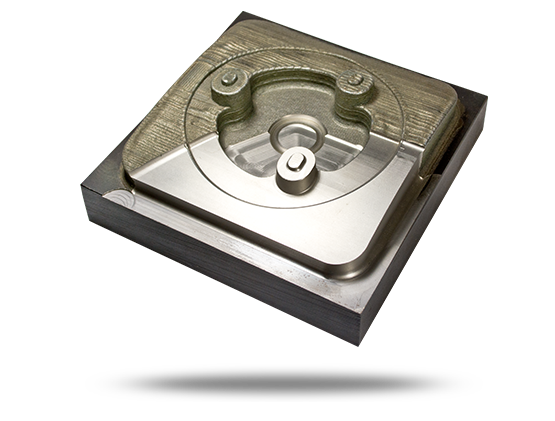

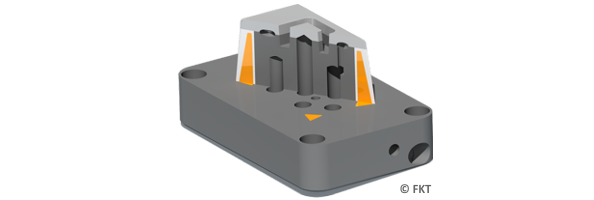

HYBRID 4 - Injection moulding tool |

||

|

|

||

Requirements

Barriers to be overcome

|

|

||

.png)