Technology Project

LasCer

Objective:

Generative processing of ceramic fiber composite structures using laser technology

Partners:

Duration: 01.04.2019 - 31.03.2021

Ceramic fibre composites

The LasCer project serves to investigate the feasibility of a completely new process for the more cost-effective production of ceramic matrix composites (CMC).

Ceramic fibre composites are currently in the focus of the aerospace and energy industry. By using them, higher process temperatures or a lower cooling requirement can be achieved, which is expected to increase the efficiency of gas turbines and reduce their weight.

The application of such materials has so far been hindered by elaborate (cost-intensive) production routes and an inadequate feasibility of design complexity. The established processes for CMC production differ mainly in the structure of the matrix, while fibre processing is largely based on the techniques of CFRP (fibre-reinforced plastics). The matrix can be produced e.g. by slurry infiltration of the fibre prepregs, by deposition from the gas phase (CVD), by pyrolysis of preceramic polymers (PIP) or infiltration with silicon (LSI). In all cases, the entire component must be subjected to heat treatment at least once, often several times.

Scope of the investigations

The process to be investigated in this project comprises the direct production of ceramic fiber composite structures by means of laser technology. In this process, ceramic fibers are to be brought together with a matrix material, which is initially in powder form and is subsequently consolidated by laser treatment by means of melting.

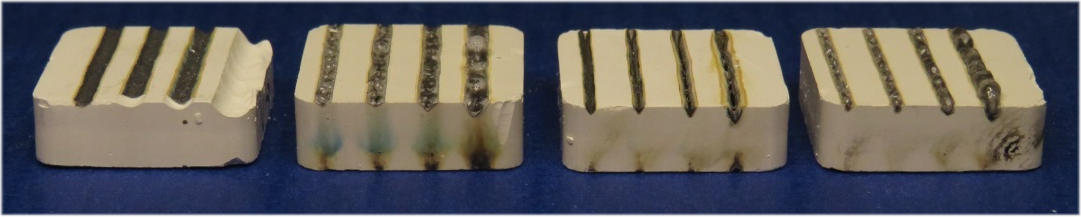

Pressed sample of powdery matrix (Y2O3, SiO2) with particles of silicon carbide (SiC)

Press specimens after the melting tests

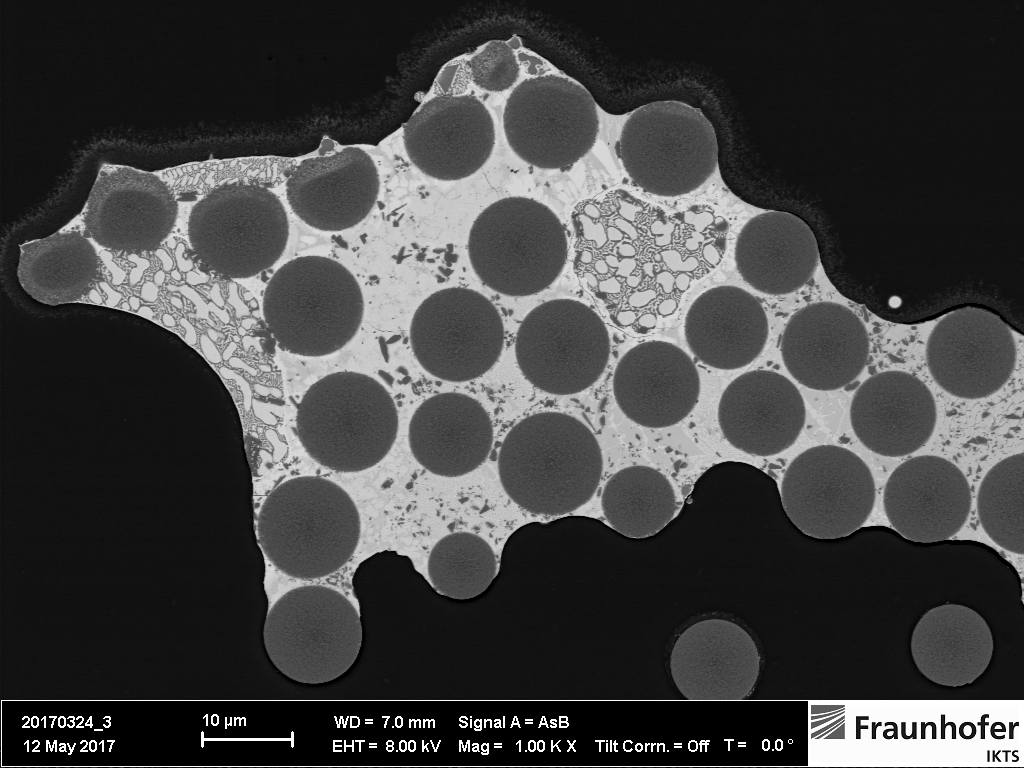

Cross section with melted CMC matrix (Y2O3/SiO2/SiC) and SiC fibre

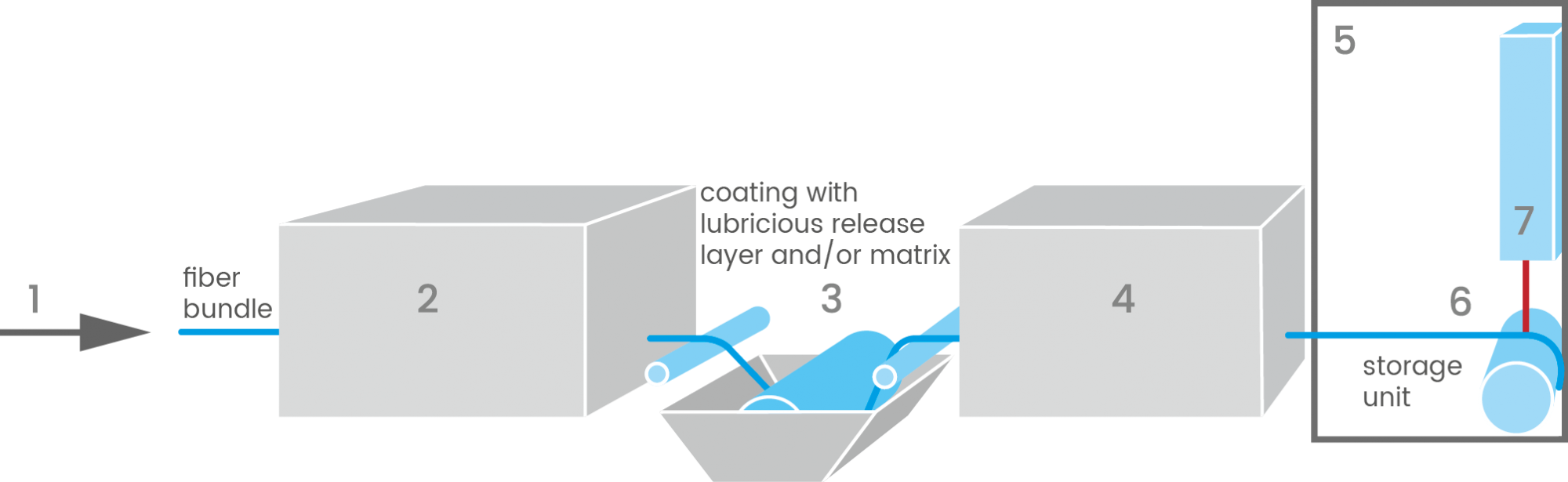

Flow of the production process

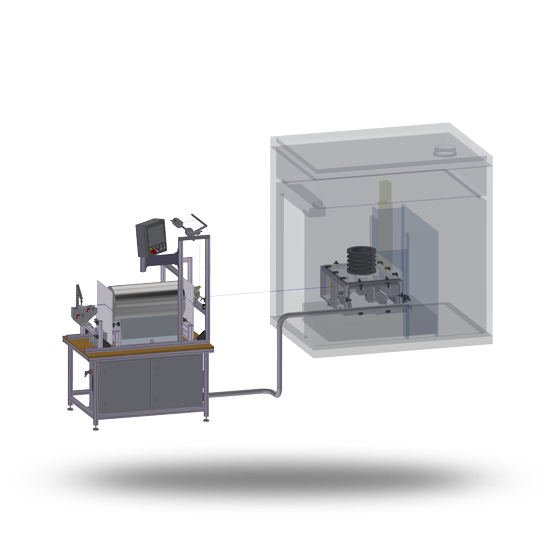

The production process (see Figure 1) starts with unwinding the fibres from the bobbin (1). The silicon carbide fibers to be used in this project have a diameter of 7 to 10 µm and are not present individually but in so-called rovings (fiber bundles). Since the fibre bundle is protected against mechanical damage by a polymeric coating, this coating must first be removed thermally. This is done by passing the roving through a tube furnace (2). In the following step, however, the matrix material must be placed between the individual fibres. The addition of the matrix powder through a nozzle in the laser process alone cannot make this possible. For this reason, the fiber bundle must be coated with the matrix powder. Based on the winding technology used in suspension-based production of CMC, the fiber bundle is to be guided through a powder suspension (3) via deflection rollers. This coats the fiber bundle between the fibers and around the outside with the matrix material. Since the properties of non-oxide CMC are strongly dependent on the fibre-matrix interaction, a separating layer between the fibre and the matrix is to be applied and tested in addition to the coating of the fibre with matrix material. For this purpose, the fiber is coated e.g. with a carbon dispenser and then directly with the ceramic matrix material. This is expected to have a positive effect on damage tolerance. The applied suspension is then dried using a tube furnace (4). The roving provided with the matrix powder is fed into the laser system (5) and deposited on a rotating mandrel by means of a combined depositing and winding unit (6). During depositing, the roving is heated locally with a suitable laser source (7). This heating is intended to cause the matrix powder to melt, densify and then solidify again. It is also important at this stage that the thermal treatment does not damage the fibre material. This means that oxidation processes and melting of the fibres must be avoided. An additional post-infiltration after the melting and solidification process is not required.

Figure 1: Process diagram