Challenge

Status Quo.

The great promise of additive manufacturing lies in its ability to provide the reproducibility and reliability of current production processes while accommodating customer specifications and designs which are adapted to the desired application and not bound by available production methods. Alongside consumer goods such as jewelry, art and decorative items, competitive solutions already exist for some industrially-relevant product classes. The entry threshold for product development and production has been drastically reduced by additive manufacturing. Furthermore, the process offers an extremely efficient and low-cost production of components even for small batch sizes. This is a result of the short production periods without huge costs for complex tool-making, storage and transport. In summary: AGENT-3D intends to exploit the many opportunities and still-to-be-discovered potentials of additive manufacturing. This truly is a new industrial revolution!

Intentions

Foster innovations.

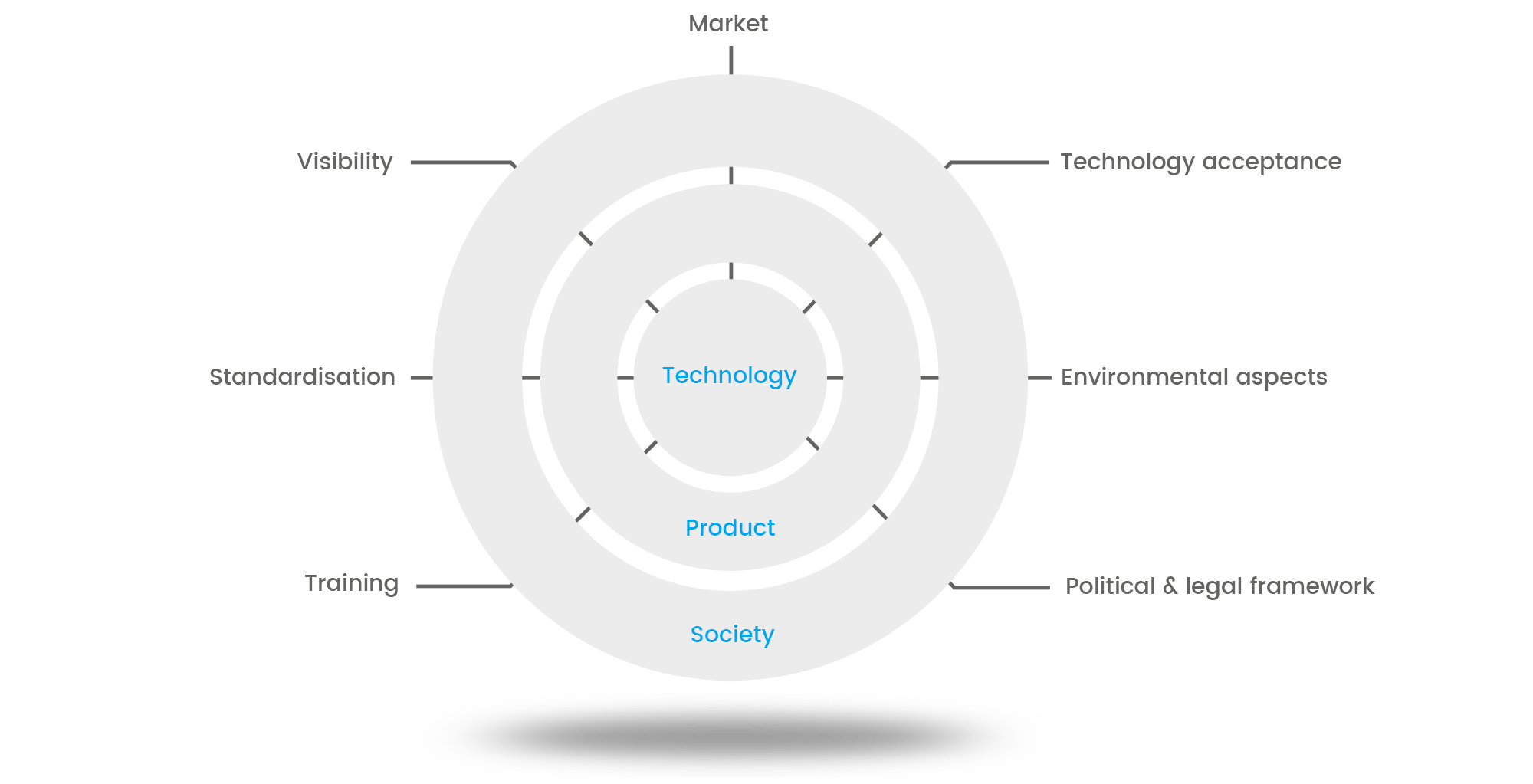

The primary objectives of AGENT-3D can be broken down into technological, market-based and social components.

Here an overview:

Our mission.

Paradigm shift in production

Additive manufacturing brings the right material to the right place without tooling and with high precision, flexibility, resource efficiency and cost-effectiveness. AGENT-3D will pave the way for the industrial implementation of additive manufacturing as an innovative production process.

Functionally-adapted products

Multi-material systems with integrated intelligence will allow the manufacture of products with radically new functions and characteristic profiles. These will drive international demand and open up new markets. AGENT-3D is developing highly integrated prototype products with entirely new combinations of functions.

Individualized production

Tailor-made individual parts and large-batch series of products will be developed and produced within (primarily) virtualized process chains. Production is exclusively to demand and can be implemented on-site as well as elsewhere. AGENT-3D can demonstrate the efficient, low-cost production of small to large batches of products for various industries.

Relocation of production

Additive manufacturing has the potential to become a key technology for Germany, boosting inland production and limiting the relocation of value added and jobs to other countries. Some value-added processes can even be brought back to this country.

Germany will become the lead provider for the complete spectrum of additive manufacturing processes. Large enterprises and innovative SMEs will set the development pace to apply this key technology to the whole value chain. AGENT-3D will establish entire productive value chains in Germany.

Window to the outside

Higher recognition and acceptance of additive manufacturing can be developed by a close dialogue with society. Additive manufacturing brings vital new impulses to education and training. High priority must be placed on letting the public and professionals discover the great opportunities presented by additive manufacturing. AGENT-3D fosters confidence in industry and society through scientifically grounded developments and best-practice examples. In this way we promote a climate for Innovation.

Synergies through transdisciplinary networking of skills

Through increased transdisciplinarity and networking, the open consortium will explore new aspects of cooperation, creating space for innovation and tapping into new application fields. The networking platform AGENT-3D encourages transdisciplinary cooperation as a way to uncover entirely novel areas of application and products.

Ecological footprint

The environmental impact of materials and processes is already being evaluated during the development of additive manufacturing processes. From the outset AGENT-3D has promoted the sustainable development of additive manufacturing.

Applications and markets

Additive manufacturing supports the creation of new business models, helping to blur even further the distinction between digital and physical production. Within the transformation of product development process by additive manufacturing, socio-economic aspects will also be considered and possible models for B2B and B2C collaborations developed. AGENT-3D identifies current key applications and markets while anticipating future ones. It also delivers solutions as a basis for the industrial implementation of additive manufacturing.